By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the rapidly evolving landscape of precision manufacturing, the advent of laser metal machines has revolutionized the way industries approach metal fabrication. According to Dr. Alice Harper, a renowned expert in the field of laser technology, "The integration of laser metal machines not only enhances accuracy but also significantly reduces production time, setting a new standard for manufacturing excellence." This innovative technology employs high-precision lasers to cut, weld, and engrave various metals, providing manufacturers with unparalleled versatility and efficiency.

The advantages of using laser metal machines extend beyond mere speed and precision. These advanced systems allow for intricate designs and complex geometries that would be challenging to achieve with traditional machining methods. Additionally, the reduced thermal impact minimizes deformation and material waste, making laser metal machines an eco-friendly choice for businesses committed to sustainability. As industries continue to seek solutions that maximize productivity while maintaining quality, the role of laser metal machines in precision manufacturing will only grow in importance, shaping the future of metalworking.

Laser metal machines have revolutionized the landscape of precision manufacturing by offering unparalleled accuracy and efficiency. One of the primary benefits of these machines is their ability to execute intricate designs with minimal material waste. Unlike traditional machining processes, laser cutting utilizes focused light to precisely guide the cutting trajectory, resulting in cleaner edges and reducing the need for additional finishing processes. This not only enhances the quality of the finished product but also contributes to lower production costs and turnaround times.

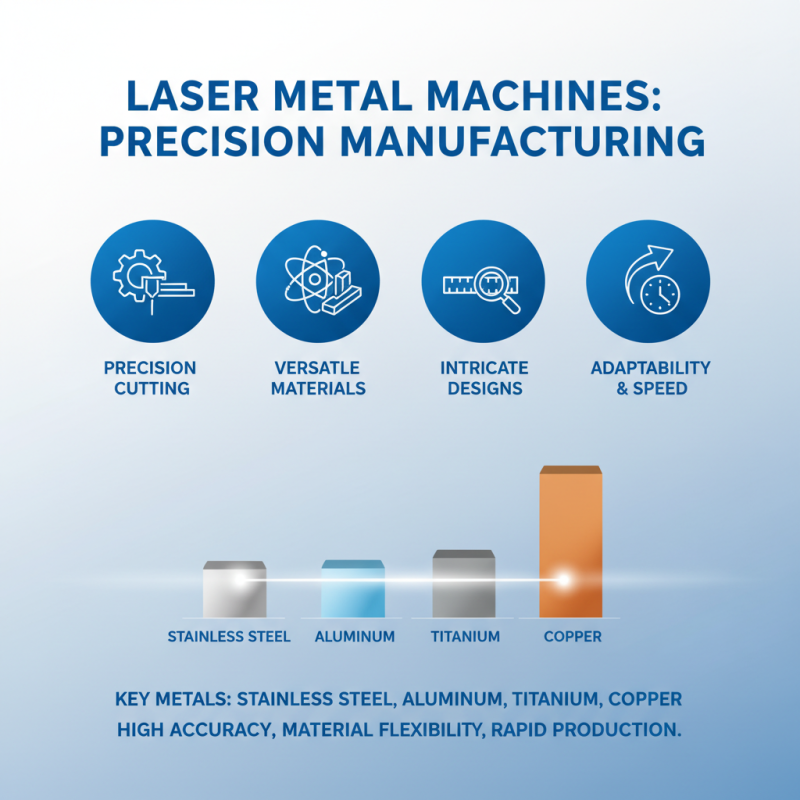

Moreover, laser metal machines provide remarkable versatility across various materials, including steel, aluminum, and titanium. This capability allows manufacturers to cater to a diverse range of industries, from aerospace to automotive, with a single machine setup. The adaptability of laser technology enables the production of complex shapes and structures that would be difficult, if not impossible, to achieve using conventional methods. Consequently, businesses can streamline their operations, reduce lead times, and maintain a competitive edge in the fast-paced manufacturing sector.

Laser metal machines have revolutionized precision manufacturing by significantly enhancing the accuracy and consistency of production processes. The advanced technology behind these machines allows for intricate designs to be executed with remarkable precision, ensuring that each component meets exact specifications. This level of detail minimizes the margin for error, which is crucial in industries where even the slightest deviation can lead to substantial cost implications and compromised quality.

Moreover, the consistency offered by laser metal machines helps streamline manufacturing workflows. Since these machines operate based on highly controlled parameters, they deliver uniform results across multiple production runs. This reliability not only boosts productivity by reducing the need for rework and quality control interventions but also fosters a stable output that clients can depend on. As industries continue to strive for efficiency and excellence, the role of laser metal technology in achieving consistent high-quality products becomes increasingly indispensable.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Enhanced Accuracy | Laser machines provide high precision cutting and engraving, allowing for intricate designs and sharp details. | Reduction in material waste and rework, leading to cost savings and improved product quality. |

| Consistency | Automated processes result in uniform production standards, ensuring every piece meets specifications. | Increased customer satisfaction and trust in product quality. |

| Versatility | Laser machines can handle various materials including metals, plastics, and composites, adapting to different production needs. | Ability to diversify product lines and explore new markets. |

| Speed | High-speed operations decrease turnaround time, optimizing production schedules. | Faster delivery times enhance competitive advantage in the industry. |

| Reduced Thermal Distortion | Laser cutting minimizes heat affected zones, preserving material integrity and properties. | Improved product durability and performance in applications. |

Laser metal machines have revolutionized precision manufacturing by significantly reducing material waste. Traditional machining processes often involve cutting away large portions of raw material, leading to considerable excess that is discarded. In contrast, laser technology employs precise cutting techniques that utilize only the necessary amount of material, allowing manufacturers to optimize their resource usage. This reduction in scrap not only conserves valuable metals but also minimizes disposal costs and environmental impact.

In addition to minimizing waste, laser metal machines enhance overall efficiency in production. The capability of these machines to cut, engrave, and weld with pinpoint accuracy means faster turnaround times for projects, streamlining the workflow in manufacturing plants. Furthermore, the automation and adaptability of laser systems allow for quick adjustments to different designs without extensive setup changes, resulting in less downtime. This efficiency translates to cost savings and enables manufacturers to respond more swiftly to market demands and customization requests, ultimately driving productivity and profitability.

Laser metal machines have become invaluable tools in precision manufacturing, offering exceptional versatility across a wide range of metal materials and thicknesses. These advanced devices can effectively work with metals such as stainless steel, aluminum, titanium, and copper, among others. This capability allows manufacturers to produce intricate designs with high accuracy, regardless of the complexity of the project. The ability to switch between different materials easily also means that businesses can adapt their production lines swiftly based on market demands or specific client requirements.

Additionally, the precision offered by laser cutting and engraving processes significantly reduces material waste, which is crucial in maintaining cost-effectiveness in manufacturing. With adjustable settings, operators can fine-tune the machines to handle varying thicknesses, enabling them to execute everything from delicate components to robust structural parts with the same level of detail. This adaptability not only optimizes production efficiency but also ensures that manufacturers can meet diverse industrial standards and specifications. Overall, the versatility of laser metal machines empowers precision manufacturing to expand its capabilities, catering to a plethora of applications across different sectors.

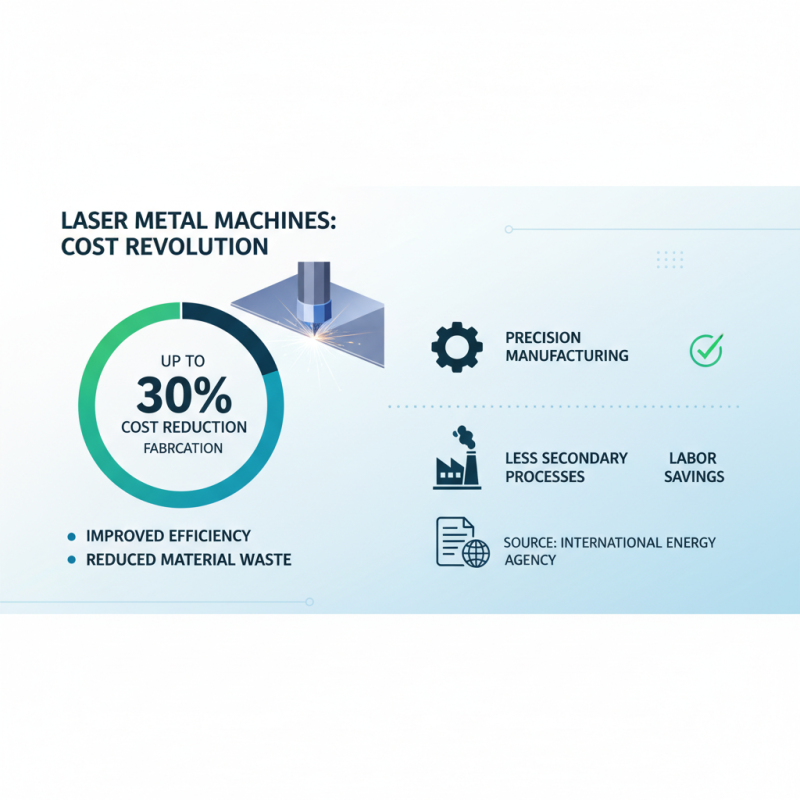

Laser metal machines have revolutionized the landscape of precision manufacturing, offering a compelling cost-effectiveness that traditional machining techniques often struggle to match. According to a report by the International Energy Agency, manufacturers utilizing laser cutting technologies can reduce fabrication costs by up to 30% due to improved efficiency and reduced material waste. This significant savings is largely attributed to the precision of laser machines, which minimize the need for secondary processes and the associated labor costs.

Furthermore, the adoption of laser technology can markedly decrease production times. A study conducted by the U.S. Department of Energy notes that laser cutting can operate at speeds up to 50% faster than conventional methods, directly translating to lower operational costs and increased output. In an era where time-to-market is crucial, companies that embrace laser metal machining are not only enhancing their production capabilities but also optimizing their budgets. This shift is not merely a trend; it represents a strategic move towards sustainability and financial viability in the competitive manufacturing sector.

Laser metal machines have revolutionized precision manufacturing by offering a multitude of benefits that enhance production processes. These machines provide improved accuracy and consistency, ensuring that every piece manufactured meets stringent specifications. Additionally, their ability to minimize material waste not only increases efficiency but also contributes to sustainability efforts within the industry.

The versatility of laser metal machines allows them to work with various metal materials and thicknesses, making them suitable for a wide range of applications. When compared to traditional manufacturing techniques, they offer greater cost-effectiveness, helping businesses to optimize their budgets. Furthermore, these machines significantly reduce production time, leading to faster turnaround rates and a more responsive manufacturing workflow. Overall, the adoption of laser metal machines in precision manufacturing holds the potential for transformative improvements across the board.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.